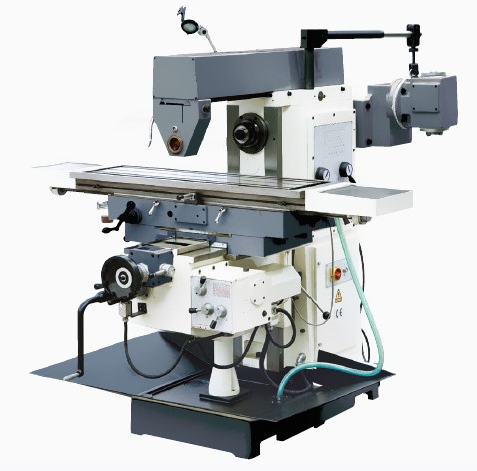

VMC850 CNC Vertical Milling muchina

Product Description

2. Dhonza hurongwa

Iwo matatu axis anotungamira njanji mbiri inotora kunze kwenyika inotenderedza mutsara njanji, ine diki ine simba uye static friction simba, yakakwirira senitivity, diki vibration nekumhanya kwakanyanya, hapana kukambaira nekumhanya kwakaderera, kukwirisa chinzvimbo, kuita kwakanakisa servo drive, uye inovandudza iko kurongeka uye kugadzikana kweiyo muchina chishandiso.

Iyo matatu axis servo mota yakabatana zvakananga neiyo yakakwira chaiyo bhora screw kuburikidza nelastic coupling, ichidzikisa epakati zvinongedzo, kuona kuti hapana kufambisa kwekutapurirana, kuchinjika kudyisa, kwakaringana chinzvimbo uye yakakwirira kutapurirana chaiko.

Z axis servo mota ine otomatiki kukiya basa, kana iri kutadza simba, inogona kukiya mota shaft kuti ibate yakasimba, kuti isatenderere, iite basa mukuchengetedza kuchengetedza.

3. The spindle group

Iro guru shaft boka rinogadzirwa neTaiwan nyanzvi inogadzira, ine yakanyanya kurongeka uye yakanyanya kuomarara. Kutakura P4 kirasi spindle yakakosha mabearings, iyo yese seti ye spindle musangano pasi pemamiriro ekushisa anogara aripo, mushure mekupedzwa kwesimba rekugadzirisa chiyero uye kumhanya bvunzo, inovandudza iyo yese seti yehupenyu hwesevhisi sevhisi uye kuvimbika kwakanyanya.

Iyo spindle inogona kuona isina nhanho yekumhanyisa kudzora mukumhanya kwayo, iyo spindle inodzorwa nemota yakavakirwa-mukati encoder, iyo inogona kuona iyo spindle yekutarisa uye yakasimba yekubaya basa.

4. Raibhurari yebanga

Raibhurari yezvishandiso zverobhoti yakaiswa padivi pekoramu. Musoro wekucheka unotyairwa uye unomiswa neiyo roller CAM meshini kana uchichinja chishandiso. Mushure mekunge spindle yasvika pachinzvimbo chekuchinja chishandiso, iyo manipulator chishandiso chekuchinja mudziyo (ATC) inopedzisa banga rekudzoka uye nekudya kwebanga.

5. Kucheka kutonhora hurongwa

Yakashongedzerwa nehombe yekuyerera inotonhorera pombi uye hombe yemvura tangi, nyatso simbisa kutenderera kutonhora, kutonhora kwepombi simba: 0.48kW, kudzvanywa: 3bar.

Chiso chemusoro chakashongedzerwa neanotonhodza nozzles, anogona kunge ari mvura kana mhepo yakatonhodzwa uye inogona kuchinjika paunoda. Maitiro ekutonhora anogona kudzorwa neM kodhi kana control panel.

Yakashongedzerwa nepfuti yekuchenesa mweya yekuchenesa maturusi emuchina.

6. Pneumatic system

Iyo pneumatic triplet inogona kusefa kusvibiswa uye hunyoro mumhepo sosi kudzivirira kukuvara nekuora kwezvikamu zvemuchina. Iro solenoid valve boka rinodzorwa nePLC chirongwa kuti ive nechokwadi chekuti spindle yakasununguka banga, iyo spindle centre inovhuvhuta, iyo spindle clamping banga, iyo spindle mhepo kutonhora uye zvimwe zviito zvinogona kupedzwa nekukurumidza uye nemazvo.

7. Lubricating system

Njanji yekutungamira uye bhora sikuruu zvinozorwa nepakati pepakati pemafuta matete. Imwe neimwe node inoshongedzerwa nehuwandu hweoiri distributor, iyo yakadzikwa uye kuverengerwa kune yakaomeswa zvikamu kuti ive nechokwadi chekuzora yunifomu yeimwe neimwe inotsvedza nzvimbo, zvinobudirira kudzikisa kupokana, kunatsiridza kufamba chaiko, uye kuve nechokwadi chehupenyu hwesevhisi yebhora screw uye gwara renjanji.

8. Kudzivirirwa kwechigadzirwa chemuchina

Muchina uyu unotora kamuri yekudzivirira, iyo isingango dzivirira kupfava kweinotonhorera, asi zvakare inovimbisa kushanda kwakachengeteka uye kutaridzika kwakanaka. Yega yega njanji yechishandiso chemuchina ine chivharo chekudzivirira kudzivirira machipisi uye chinotonhodza kupinda mukati memudziyo wemuchina uye kudzivirira njanji yegwara uye screw yebhora kubva pakusakara nekuora.

9. Chip kubvisa system (optional)

Iyo Y axis inopatsanura inodzivirira chimiro inoita kuti machipisi esimbi anogadzirwa mukugadzirisa maitiro awire akananga pamubhedha, uye yakakura yakarerekera chimiro mukati memubhedha inoita kuti machipisi esimbi atsvedzeke zvakanaka kune ketani ndiro yeketani chip discharge mudziyo pazasi pemuchina chishandiso. Iyo ketani ndiro inofambiswa neiyo chip discharge mota, uye machipisi anotakurwa kuenda kumota yekuburitsa chip.

Chain chip discharging mudziyo ine hukuru hwekutakura, ruzha rwakaderera, chivharo chekudzivirira chakawandisa, mashandiro akachengeteka uye akavimbika, anogona kushandiswa kune akasiyana siyana emarara uye coil.

Product Description

Zvinotsanangurwa

| Model | VMC850L | Unit | ||

| Worktable | Worktable size | 1000×500 | mm | |

| Max. Mutoro uremu | 600 | kg | ||

| T slot size | 18×5 | mm× Chikamu | ||

| Processing range | Max. kufamba kwetafura - X-axis | 800 | mm | |

| Max. slide kufamba - Y axis | 500 | mm | ||

| Max. spindle kufamba - Z axis | 500 | mm | ||

| Distance from spindle end face to worktable | Max. | 650 | mm | |

| Min. | 150 | mm | ||

| Distance from spindle center to guide njanji base | 560 | mm | ||

| Spindle | Taper (7:24) | BT40 |

| |

| Speed range | 50~8000 | r/min | ||

| Max. kubuda torque | 48 | Nm | ||

| Spindle mota simba | 7.5/11 | kW | ||

| Spindle drive mode | Synchronous toothed belt |

| ||

| Tool | Tool handle model | MAS403 BT40 |

| |

| Dhonza muenzaniso wembambo | MAS403 BT40-I |

| ||

| Feed | Kukurumidza kufamba | X axis | 24(36) | m/min |

| Y axis | 24(36) | |||

| Z axis | 24(36) | |||

| Simba rematatu-axis drive mota (X/Y/Z) | 2.3/2.3/3 | kW | ||

| Torque yematatu-axis drive mota (X/Y/Z) | 15/15/23 | Nm | ||

| Feed rate | 1-20000 | mm/min | ||

| Tool | Fomu remagazini | Manipulator (HAT inosarudza) |

| |

| Chishandiso chekusarudza maitiro | Bidirectional yepedyo yekushandisa sarudzo |

| ||

| Kukwanisa kwemagazini | 24 |

| ||

| Maximum tool kureba | 300 | Mm | ||

| Maximum tool uremu | 8 | Kg | ||

| Max.cutter musoro dhayamita | Full | Φ78 | Mm | |

| Pedyo nebanga risina chinhu | φ120 | Mm | ||

| Chishandiso chekuchinja nguva (chokushandisa kune chishandiso) | 1.8 (Bamboo hat8S) | S | ||

| Positioning kururama | JISB6336-4:2000 | GB/T18400.4-2010 |

| |

| X axis | 0.016 | 0.016 | Mm | |

| Y axis | 0.012 | 0.012 | Mm | |

| Z axis | 0.012 | 0.012 | Mm | |

| Dzokorora kurongeka kwechokwadi | X axis | 0.010 | 0.010 | Mm |

| Y axis | 0.008 | 0.008 | Mm | |

| Z axis | 0.008 | 0.008 | Mm | |

| Machine uremu | 4800 | Kg | ||

| Kukwana kwemagetsi | 20 | KVA | ||

| Zviyero zvakazara (L×W×H) | 2730×2300×2550 | Mm | ||